Maritime

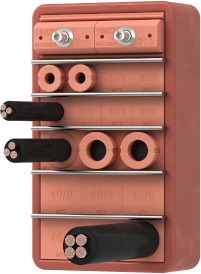

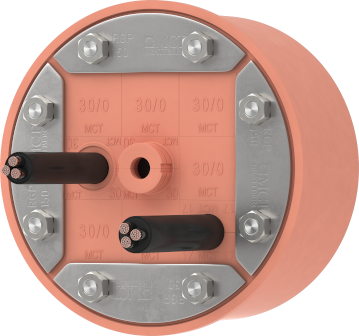

The market for maritime and offshore structures, such as ships and platforms, is very dynamic and innovative. MCT Brattberg’s cable transits originate from this market. In the early 1950s, MCT Brattberg introduced a worldwide innovation, which replaced the conventional cable glands with a single modular cable entry system. By welding steel windows into the ship’s hull or into the platform wall, an opening is created that can be filled with modular spacers in such a way that cables and pipes of various diameters are sealed. The space in front and behind it is thus protected against water, gas and fire penetration. In addition to the regular penetrations, MCT Brattberg also offers various high-pressure penetrations in this market, for use in, for example, the subsea constructions of platforms and even for the protection of submarines, both with internal penetrations and external penetrations. Also view the projects and examples from practice .

Ship-building

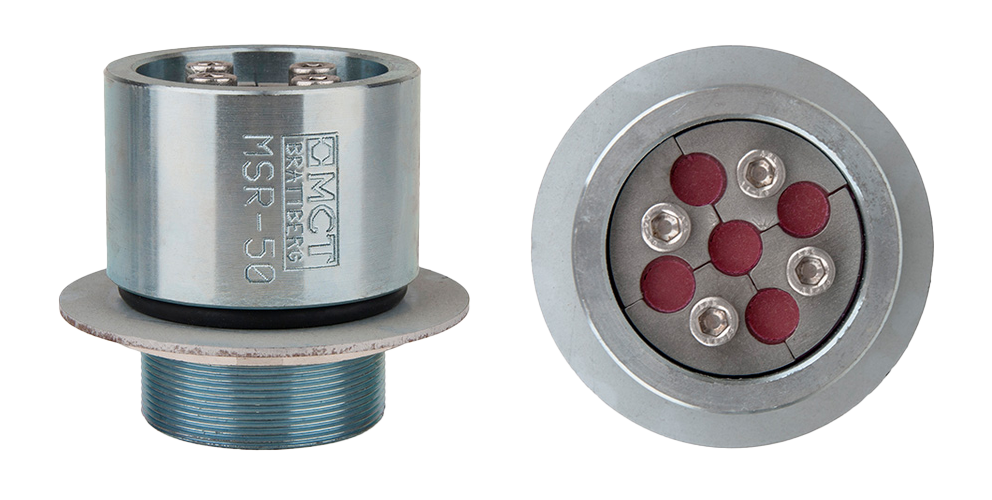

In shipbuilding, the modular cable and pipe transits from MCT Brattberg have been an established value for many decades when it comes to passive safety on board. Cable penetrations are found throughout the ship: welding windows, of the RGS type, in all walls and floors, round windows in decks, box penetrations in cabinets, switchboards and consoles, Atex certified penetrations for Ex zones and high pressure penetrations in special applications. These cable and pipe transits are installed as a passive safety barrier, both against the passage of water and the temporary prevention of fire penetration, the penetration of (toxic) gases and the spread of smoke. Since the MCT Brattberg transits provide passive safety, there is sometimes the danger that their importance is underestimated. Unfortunately, despite advancing technology on ships, fires and collisions still occur with some regularity. It is precisely at those moments that the MCT Brattberg transits prove their worth, both in preventing calamities and personal injury and in keeping technical installations intact.

Also view the projects and examples from practice .

matching products

Offshore oil & gas

Today, MCT Brattberg transit systems are widely used in the Oil & Gas market:

- production platforms

- accommodation units

- drilling and jack-up rigs

- semi-submersible platforms

- pontoons and exploration ships

But also in refineries, including at:

- various refining processes

- storage tanks

- catalytic cracking plants

- distillation installations

- recovery plants

Specific oil & gas transits

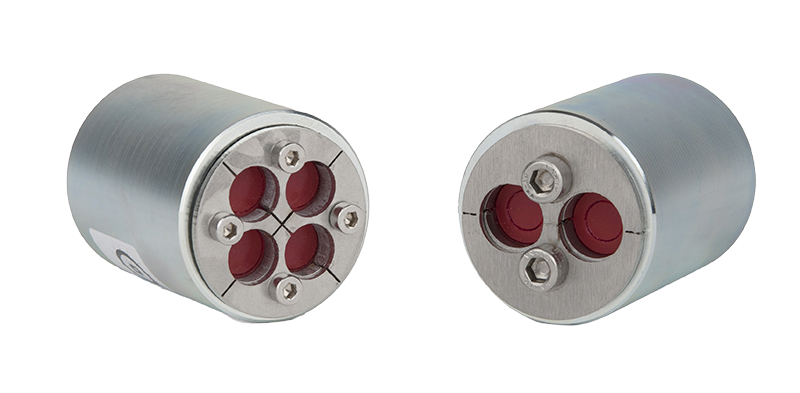

In addition to regular penetrations, high-pressure penetrations are used in this segment, for example the RGPH tested up to 120 bar. Other types of rubber are also used in some cases, for example because of their relative insensitivity to contact with oil.

Also view the projects and examples from practice .

matching products

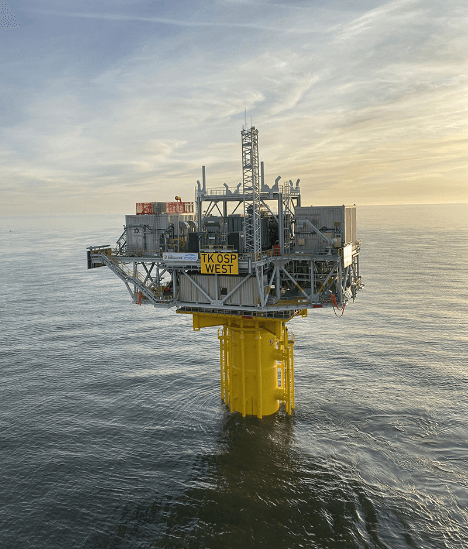

offshore wind

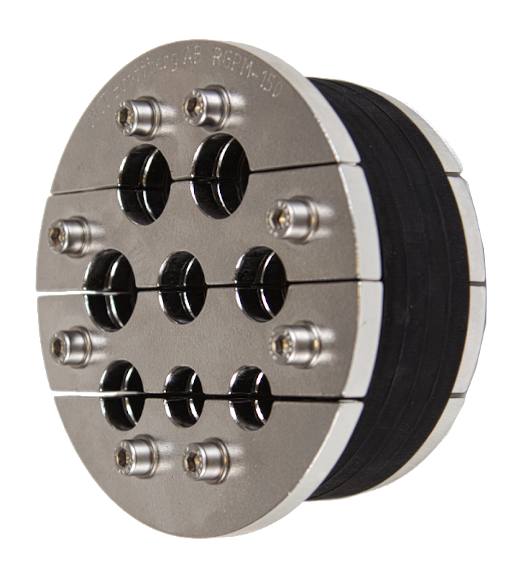

Offshore windmills are increasingly seen at sea, usually centered as part of a wind farm. Wind turbines at sea make an important contribution to making energy production more sustainable. A good and low-maintenance operation of these wind turbines is of course of great importance. The cable transits of MCT Brattberg also play an important role in this. The standard penetrations are often used in the head of the windmill, to prevent the possible spread of fire from the turbine located here. In addition, many of the supply and return cables entering the mills below the waterline are sealed with an RGPM annular pressure-tight seal. These round RGPM penetrations are placed around the so-called J-tube, a J-shaped tube that protrudes through the wall of the submerged foot, also called monohull, to safely anchor this J-tube in the windmill. MCT Brattberg cable and pipe transits are also often used on the transformer platforms, which form the connecting link between the surrounding wind turbines and the mainland.

Also view the projects and examples from practice .