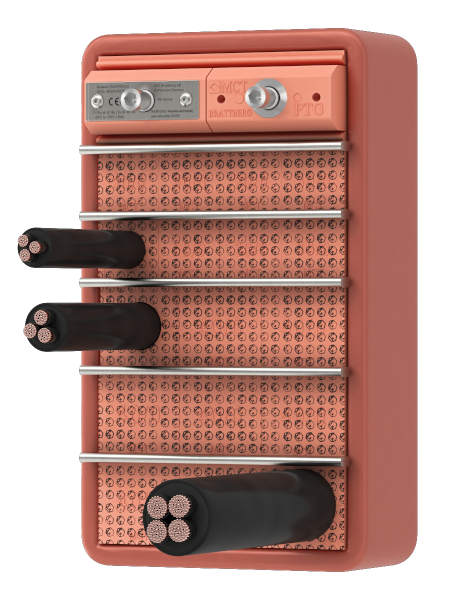

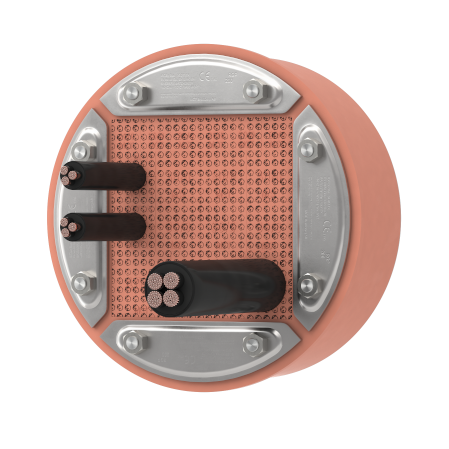

IEC-Ex and ATEX approved cable transits

For situations where MCT Brattberg transit have to be placed in an explosive environment, MCT Brattberg has developed a special line of IEC-Ex and ATEX approved frames and filling materials. All rubber filling materials for the EX penetrations have a special black marking. All Ex certified products from MCT Brattberg are suitable for both Zone 1 and Zone 2 .

To guarantee that the ATEX certified materials are classified as part of a certified transit, a few simple conditions must be met when ordering. When ordering, it must be stated in advance for which zone (1 or 2) the transit is intended. In addition, the frames and components, including the (mandatory) lubricant, must always be ordered in one complete order.

Properties

- Fire retardant (EN 1366 tested, A0, A60, H120)

- Protection against pressure, water, gas, smoke, explosion, vibration, noise, radioactive radiation and vermin

- Controllable, reduces the chance of error during assembly

- Tested and certified by virtually all classification societies

- 25 year warranty if installed according to installation instructions

Download:

Verschillende typen

RGB – Collapse

RGP – Installation

RGS – Welding

Certification

An explosion-proof transit is a matter for the entire system. There should be no weaknesses. All modules complement and reinforce each other, from the smallest detail to the larger framework. Each part is constructed to withstand the impact of an explosion. Regardless of different cable and pipe diameters, an MCT Brattberg transit meets the requirements for offshore and onshore. The frames are cut, welded, ground, painted and stamped with logo and date.

The Lycron in the inserts is a synthetic halogen-free polymer specially formulated to withstand fire, explosion, temperature changes, ageing, vibration, radiation and vermin. The inserts are injection molded for accuracy. The dimensions have become the industry standard and have proven to be durable over time.

MCT Brattberg Ex cable glands are approved by DNV-GL and meet the quality and environmental standard requirements of ISO 9001, 14001 and OHSAS 18001, we also comply with the ATEX directive 2014/34/EC and the IECEx requirements.

IEC-Ex & ATEX

Ex does not only concern electrical equipment, but all equipment and protective systems for use in potentially explosive atmospheres. In all buildings in the world where there is a risk of explosion, the equipment and protection systems must bear an Ex or ATEX certificate.

IECEx stands for the certification by the International Electrotechnical Commission for Explosive Atmospheres. To be IECEx certified, all products must go through a controlled process by the International Electrotechnical Commission to ensure they meet minimum safety requirements. This process will determine whether the products can be used in hazardous or potentially explosive locations.

The ATEX directive requires the product to be marked with the CE marking, the EX marking and the equipment coding:

II2GD Ex eb IIC Gb Ex tb IIIC Db T -60 ° c to +70 ° c

II = Area and Mining

2 = Zone 1/21 (1=Gas 21=Dust)

GD = Gas & Dust

Ex eb = Increased safety, b=zone 1,2

IIC = All gases approved

Gb = Gas zone 1 ( Zone 1 is also approved in zone 2. NOT ZONE 0 )

Ex tb = Dust Enclosure 6 (IP)

IIIC = Conductive dust, also approved for A and B. A=Combustible flying particles, B=non-conductive dust.

Db = Zone 21, dust also zone 22

-60°c to +70°c = Ex working temp min/max

Hulp nodig?

Our expert in the field of cable penetrations in Ex zones is happy to help you.

Maurice Welbie

m.welbie@tttbv.com

024 366 7472